The Most Common Dumpster Rental: Understanding the Basics

Dumpsters have been a basic service for renovations, builds, cleanouts, landscaping, and much more, for a long time in South Carolina.

The 20-yard dumpster is best known because it is the most frequently rented dumpster of all various sizes and types. For all these reasons and more, it remains the preferred solution to diverse requirements, due to its versatility, cost and practicality.

What Is a 20-Yard Dumpster

A 20-yard dumpster is a container that holds 20 cubic yards of waste. By way of comparison, that’s about the same as six pickup truck loads of debris. Its measurements are usually somewhere in the vicinity of 22 feet long, 7.5 feet wide and 4.5 feet tall, with slight differences based on the supplier.

This size tends to deliver an appropriate ratio of capacity while still allowing maneuverability for most residential and commercial jobs. It has the capacity to deal with large volumes of waste but will not dwarf your driveway or become unwieldy on a job site.

Why Is the 20 Yard Dumpster the Most Common Rental

The 20-yard dumpster is one of the most popular options available in South Carolina, and there are many reasons for this:

- Versatility

- 20 Yard Dumpsters can hold a broad range of materials, such as:

- Construction waste (wood, drywall, flooring, roofing shingles)

- Household junk (pregnancy / baby gear, furniture, appliances, boxes)

- Yard debris (branches, vegetation, bushes)

- Small to medium renovation debris (bathroom or kitchen remodels)

Because these projects are common among homeowners and contractors, its capacity is best suited for those that are on a medium-scale.

Cost-Effectiveness

When it comes to waste management, renting a 20-yard dumpster is an affordable option. It gives plenty of room while not costing as much as larger dumpsters such as a 30- or 40-yard dumpster. There is no need to monetize multiple trips to a landfill, which saves both time and money for most projects.

Ease of Placement

The 20-yard choice is small enough to park comfortably in driveways, parking lots, or even smaller spaces, unlike some of the larger dumpsters. Recommended for: Residential areas and urban settings due to space constraints.

Adherence to Local Regulations

Cities and neighborhoods often have restrictions on dumpster size and placement. A 20-yard dumpster usually satisfies the criteria, so it can be a convenient option for compliance.

Manageable Weight Limits

The capacity and weight limits of a 20-yard dumpster can handle the majority of materials without violating transportation limits. It may also help avoid overage fees or trouble at pickup.

20-Yard Dumpster: Common Uses

The 20-yard dumpster is useful for many types of projects:

Home Renovations

Whether you’re replacing floors, renovating a bathroom or remodeling a kitchen, a 20-yard dumpster can accommodate the debris, including old cabinets, tiles or drywall.

Garage and Basement Cleanouts

A 20-yard dumpster is a great option for homeowners who are clearing out an entire home of furniture, boxes, and junk.

Landscaping Projects

The dumpster is ideal for all yard cleanups, such as branches, grass, soil, and other landscaping waste.

Roofing Projects

The 20-yard dumpster is another popular option for roofing jobs especially if you are going to be replacing asphalt shingles or other residential roofs that are single-layered.

Small Construction Projects

Light commercial, room additions, minor renovations or demolitions are examples of projects where contractors often rent 20-yard dumpsters.

Things to Know When Renting a 20-Yard Dumpster

The 20-yard dumpster is highly versatile, but there are a few things to consider so it works well for you:

Type of Waste

Some products, like hazardous waste, might be prohibited from standard dumpsters. Always ask the rental company for guidelines.

Weight Limits

20-yard dumpsters are quite large, capable of holding a range of materials — but if you exceed the pick-up weight, overage fees may apply. Watch out for heavy debris such as concrete or dirt.

Space Requirements

However, the maximum measurement of 20 yards is still large compared to one of the mini bins and space will be required for both placement and access.

The 20-yard dumpster is a popular rental size in Charleston, because it strikes the balance of size, price and versatility.

It can service a variety of projects; from home renovation and cleanouts to landscaping and construction. Easily providing enough space without being too large for spaces or budgets, the 20-yard dumpster is the popular choice for residential, contractor and business projects. This dependable size is probably the best place to begin when planning your next project for efficient and effective waste management.

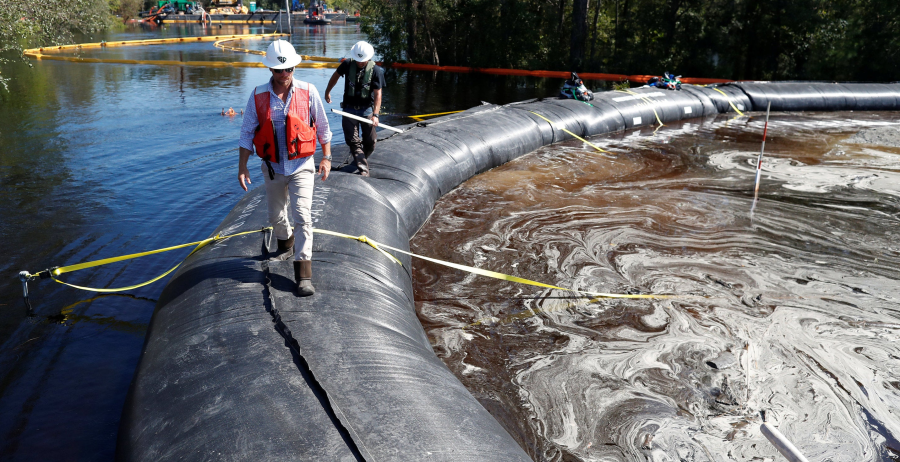

As Chicago and the surrounding areas continue to suffer from problems associated with aging water lines, increased flooding, and stormwater pollution, the construction, finance, and real estate must get their act together to save the local environment.

As Chicago and the surrounding areas continue to suffer from problems associated with aging water lines, increased flooding, and stormwater pollution, the construction, finance, and real estate must get their act together to save the local environment.